콘텐츠

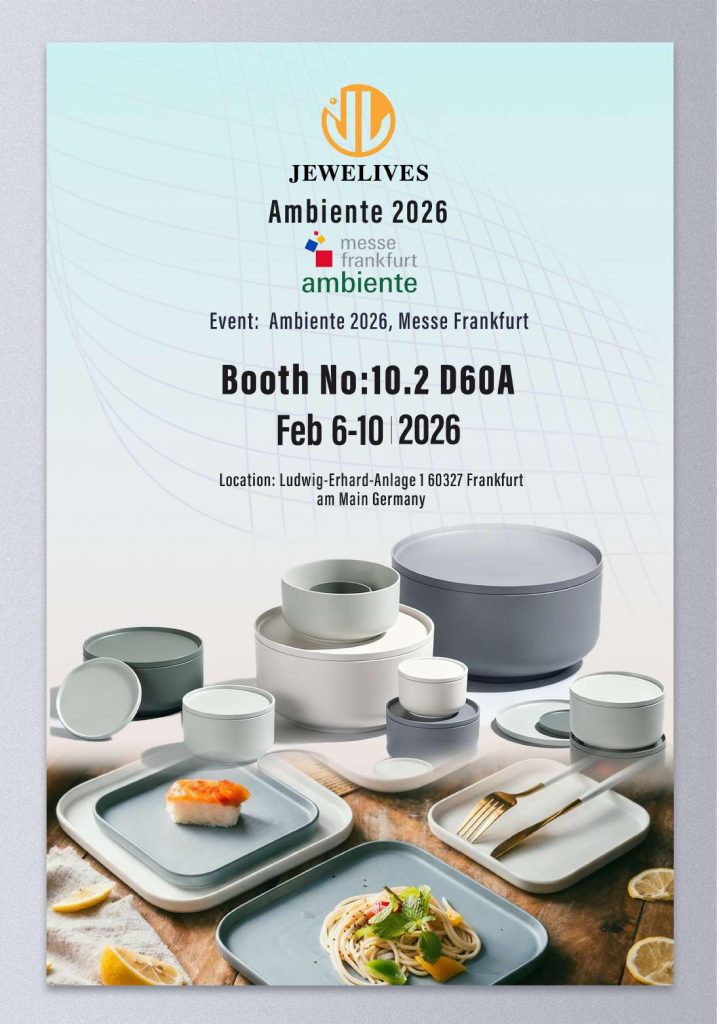

Meet Jewelives at Ambiente 2026 in Frankfurt – Your Trusted Silicone Products Manufacturer

We are pleased to announce that our company will be exhibiting at Ambiente 2026, one of the world’s leading international trade fairs for consumer goods, held at Messe Frankfurt in Germany. This exhibition provides an excellent opportunity to connect with global buyers, showcase our latest silicone innovations, and discuss future cooperation face to face.

Who We Are

We are a professional silicone products manufacturer with over two decades of production experience. As a production-oriented factory, we specialize in developing and manufacturing silicone products that combine functionality, safety, and modern design. Our focus has always been on delivering stable quality, flexible customization, and reliable supply for international markets.

Our factory operates under strict management systems and holds multiple internationally recognized certifications, including BSCI, ISO 9001, and ISO 14001, ensuring ethical production, consistent quality, and environmental responsibility.

Our Main Silicone Product Categories

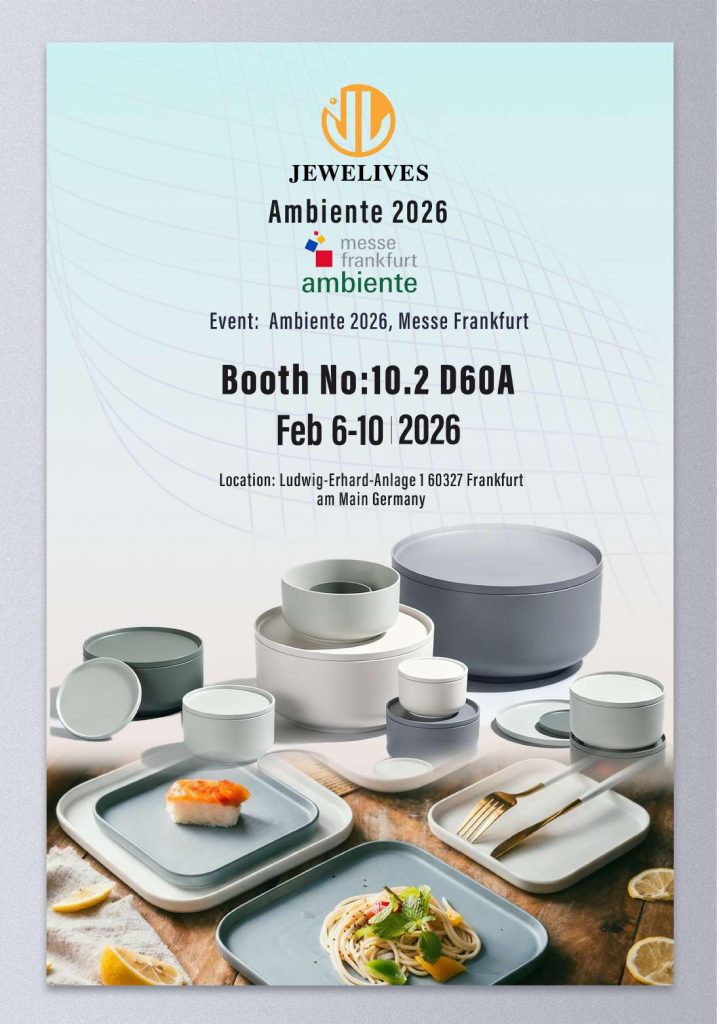

At Ambiente 2026, we will present a wide selection of food-grade, BPA-free silicone products, including:

Silicone baby products – feeding accessories designed for safety, softness, and daily use

Silicone kitchen products – cooking utensils, bakeware, and food storage solutions

Silicone pet products – durable and pet-safe items for everyday care

Silicone drinkware – reusable cups, bottles, and travel-friendly designs

Many of the products on display are newly developed designs, reflecting current market trends and consumer preferences. OEM and ODM customization options are available to support brand-specific requirements.

Strong Factory Capabilities

Our manufacturing facility is equipped to handle both standard orders and customized projects efficiently. With advanced production equipment, experienced technicians, and a dedicated R&D team, we are able to support:

Stable mass production

Custom molds and product development

Strict quality control from raw material to final packaging

Fast sampling and flexible order quantities

These capabilities allow us to serve customers across Europe, North America, and other global markets with confidence.

Visit Us at Ambiente 2026

We sincerely invite buyers, distributors, and brand owners to visit our booth at Ambiente 2026 and explore our latest silicone product collections.

Exhibition Details:

Event: Ambiente 2026

Venue: Messe Frankfurt

Location: Ludwig-Erhard-Anlage 1, 60327 Frankfurt am Main, Germany

Meeting in person allows us to better understand your needs, share product ideas, and discuss potential cooperation opportunities in a more efficient and transparent way.

Let’s Connect in Frankfurt

Whether you are looking for a reliable silicone products factory, exploring new product ideas, or searching for long-term manufacturing partners, we look forward to meeting you at Ambiente 2026.

If you would like to schedule a meeting in advance, please contact us before the exhibition. Our team will be happy to arrange a dedicated time to discuss your project in detail.