Contents

When it comes to baby feeding accessories, choosing the right bib can make mealtime easier and mess-free. In this comprehensive guide, we’ll explore the ins and outs of silicone bibs, from their material composition to their advantages and disadvantages. As a professional silicone factory specializing in custom silicone bibs, we will also share insights into the production process and how to select the best bibs for your business.

What Are Silicone Bibs?

Silicone bibs are innovative feeding accessories designed to protect babies’ clothing during mealtime. Unlike traditional fabric bibs, they are made from food-grade silicone, a material that is hypoallergenic, BPA-free, and phthalate-free. This section will cover the different types of silicone bibs and their intended users.

Silicone bibs are crafted from high-quality, food-safe silicone that is gentle on a baby’s skin. There are various styles available, including adjustable neck bibs, full-coverage bibs, and food-catcher pocket bibs designed to minimize spills and messes. Primarily used by parents and caregivers for infants and young children during feeding times, silicone bibs have become a staple in many households.

![]()

![]()

Advantages of Silicone Bibs

— Baby Feeding Bibs Are Safe and Non-Toxic: Made from BPA-free silicone, these bibs ensure that babies are not exposed to harmful chemicals.

— Feeding Bibs Are Adjustable in Size: Most silicone bibs come with adjustable closures that grow with the baby, providing a comfortable fit throughout different stages of development.

— Silicone Bibs Are Easy to Clean: Simply wipe them down with a damp cloth or toss them in the dishwasher for effortless cleaning.

— Food Catcher Bibs Avoid Food Waste: The integrated catch-all pocket catches food before it hits the floor, reducing waste and making cleanup easier.

— Baby Silicone Bibs Are Easy to Carry Around: Lightweight and compact, silicone bibs can be easily folded and packed for meals on the go.

— Baby Silicone Bibs Are Cute and Durable: Available in a variety of colors and designs, they are both aesthetically pleasing and built to last.

Disadvantages of Silicone Bibs

— Silicone Bibs Are Slightly More Expensive: Due to the higher quality of the material and manufacturing process, silicone bibs can be pricier than their plastic counterparts.

— Silicone Bibs Need to Be Stored Carefully: To maintain their integrity, silicone bibs should be kept away from sharp objects that could puncture or scratch the surface.

![]()

![]()

How to Care for and Clean Silicone Bibs

– Rinse bibs immediately after use to prevent food residue from sticking.

– Wash them either by hand with mild soap or place them in the dishwasher.

– Store in a dry area, preferably hanging or flat to avoid any creasing.

How to Choose Silicone Bibs

— If You Are the Parent of a Baby: Consider features such as adjustability, ease of cleaning, and the presence of a food catcher.

— If You Are a Distributor or Brand Owner: Look for a reputable silicone factory that offers customization options and maintains high-quality control standards.

![]()

![]()

How Are Silicone Bibs Produced?

– First Draft of the Drawing: Design concepts are sketched out based on client specifications.

– Moulding: High-precision molds are created to ensure consistent quality during mass production.

– Production: The silicone material is poured into the molds and undergoes a curing process.

– Quality Control: Each bib is inspected for defects before proceeding to the next step.

– Baking: The curing process continues to ensure the material is fully hardened.

– Packed and Shipped: Once approved, the bibs are carefully packaged and dispatched to the customer.

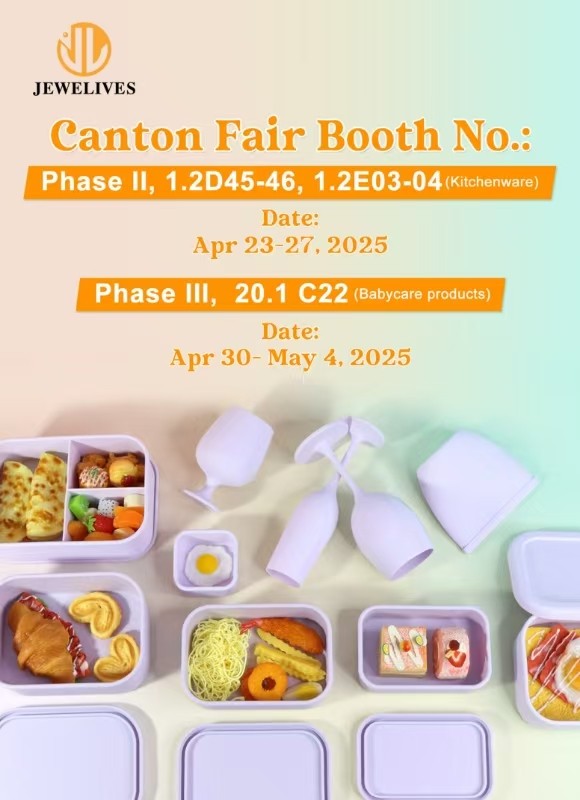

At JEWELIVES, we pride ourselves on being a leading silicone factory that offers custom silicone bibs tailored to the needs of wholesalers. Our commitment to quality and customization ensures that every bib meets the highest standards. Partner with JEWELIVES to provide your customers with safe, durable, and stylish silicone bibs that make mealtime a breeze. Contact us today to learn more about our wholesale offerings and how we can support your business growth.