Contenu

In today’s fast-paced world, maintaining proper hydration is more crucial than ever before. However, traditional water bottle caps can be cumbersome to open and close, especially when you’re on the go. That’s why we’ve developed a revolutionary Water Bottle Cap that takes hydration convenience to new heights. In this article, we will explore how our custom water bottle cap integrates seamlessly with our silicone water bottles, enhancing your daily hydration routine.

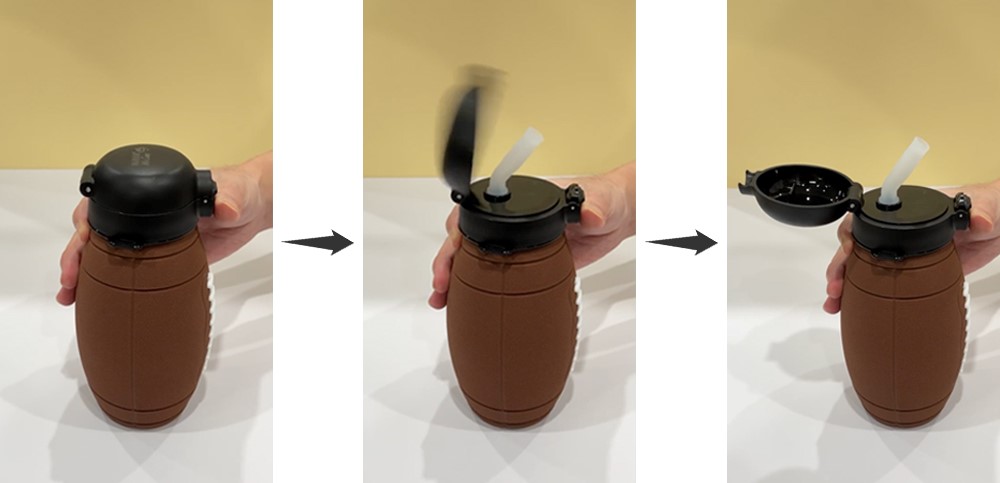

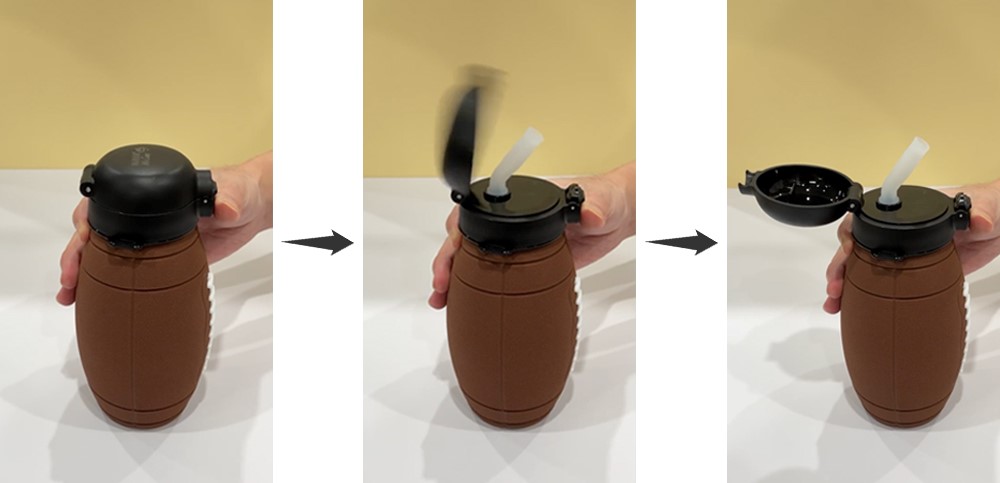

Our Water Bottle Cap is designed to make hydration simple and hassle-free. Unlike traditional screw-on caps that require both hands to open, our cap features a convenient one-hand press mechanism. This means you can easily access your drink without having to put down what you’re holding, making it perfect for busy professionals, parents, or anyone who needs to stay hydrated while multitasking.

The Benefits of One-Handed Operation

The traditional method of opening a water bottle involves twisting off a cap, which can be time-consuming and inconvenient. Our Water Bottle Cap, however, allows for quick access with just a single press, saving valuable seconds throughout the day. Whether you’re commuting, exercising, or simply need a quick sip, this feature ensures that hydration is always within reach.

One of the key benefits of this design is its applicability in various scenarios. For example, drivers can easily take a sip without taking their eyes off the road, ensuring safety and convenience. Similarly, athletes can hydrate during intense workouts without interrupting their flow. Parents can manage multiple tasks while ensuring their children stay hydrated, thanks to the cap’s intuitive design.

Leak-Proof Design with Waterproof Rubber Seal

Leakage is a common issue with many water bottles. To address this, our Water Bottle Cap includes a durable waterproof rubber seal that ensures no spills or leaks. This feature is particularly useful for those who carry their bottles in bags or backpacks, as it prevents water from seeping into sensitive electronics or documents.

Gravity Ball for Easy Drinking

A unique aspect of our Water Bottle Cap is the inclusion of a gravity ball, which enables users to drink comfortably even when the bottle is lying flat. This feature is ideal for individuals who spend extended periods in bed or who need to consume fluids without lifting the bottle. It’s also beneficial for children who might struggle to lift heavy bottles, ensuring they can hydrate effortlessly.

Customization Options for the Water Bottle Cap

As a leading manufacturer of silicone products, we pride ourselves on our ability to create custom water bottle caps tailored to specific needs. Whether you’re looking for a particular color, logo, or design, our team can work closely with you to ensure that your vision becomes a reality. This customization option not only enhances the aesthetic appeal of your silicone water bottle but also provides a personal touch that makes it uniquely yours.

Integration with Silicone Water Bottles

Our Water Bottle Cap is specifically engineered to complement our range of silicone water bottles, offering a seamless fit that maximizes functionality. These bottles are made from high-quality silicone materials, known for their durability and flexibility. They are lightweight, easy to clean, and resistant to both heat and cold temperatures, making them suitable for all seasons.

Au BIJOUX, we are committed to pushing the boundaries of hydration technology. Our Water Bottle Cap represents the pinnacle of our efforts to create products that enhance everyday life. By combining functionality with style, we aim to provide our customers with the best possible hydration experience.