Contents

In today’s trend of pursuing a healthy lifestyle, silicone water bottles are favored by many consumers for their lightweight, durable, and drop-proof features. However, the author researched several mainstream e-commerce platforms, including Amazon, and found that the smell of silicone water bottles has become a frequently mentioned pain point in many user feedbacks. The purpose of this article is to discuss how consumers can effectively remove the smell of silicone water bottles, as well as to reveal the key process of eliminating the odor during the production process, to bring consumers a better experience.

Consumer’s Guide to Removing Smell from Silicone Water Bottles

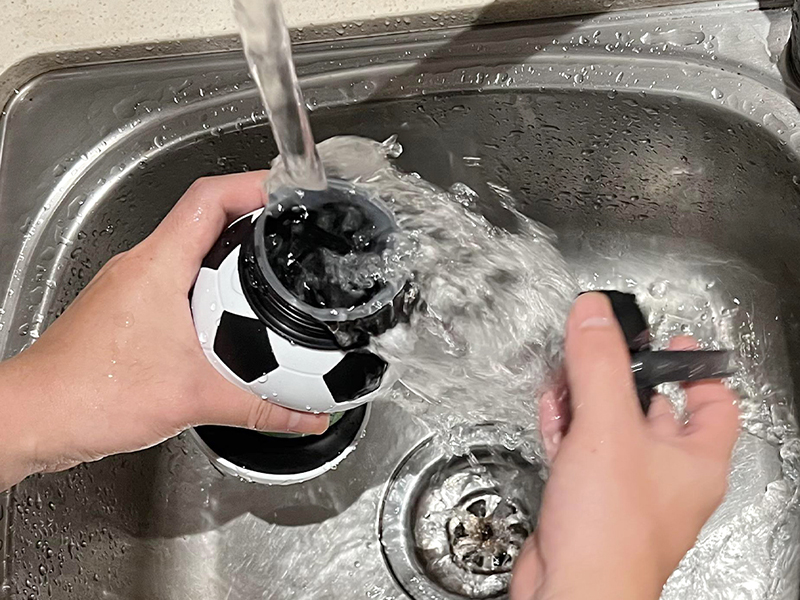

1. Wash with Warm Water

Before using for the first time, use warm water with a small amount of neutral detergent to thoroughly wash the inside and outside of the silicone water bottle, followed by rinsing with running water, this step will help to remove the impurities attached to the surface and the initial smell.

2. Boiling Water Immersion Method

Pour boiling water into the water bottle, cover tightly, and leave it for a few hours or overnight, high temperature helps accelerate the release of smell molecules. Pour off the water the next day, rinse it out again, and dry it naturally.

3. Natural Remedy: Lemon Juice/Vinegar

Add a few drops of lemon juice or white vinegar to the water and soak the bottle in the solution for a few hours – the natural acidity neutralizes the odor – and rinse thoroughly afterward.

4. Baking Soda Works Wonders

Baking soda and water mixed into a paste, evenly coated in the inner wall of the water bottle, and left for some time after rinsing, the ability of baking soda decontamination and deodorization should not be underestimated.

Smell Management in the Production Process

1. Selection of Raw Materials

Source control is key. High-quality, low-VOC (volatile organic compound) food-grade silicone raw materials can fundamentally reduce the possibility of smell.

2. Optimisation of Release Agents

The release agent is a major source of odor. The adoption of odorless, environmentally friendly food-grade release agents and thorough cleaning after production ensures that release agent residues are reduced to a minimum.

3. Secondary Vulcanization of Silicone Water Bottles

After the silicone water bottles have been molded, they need to go through a secondary vulcanization process, i.e. further curing at high temperatures, which not only enhances the physical properties of the product but also helps to completely evaporate any residual odor molecules.

4. Efficient Ventilation and Storage of Silicone Water Bottle

After production, the products are placed in a well-ventilated environment to naturally emit the residual odor, and avoid stacking for a long time in a closed space to reduce the accumulation of odor.

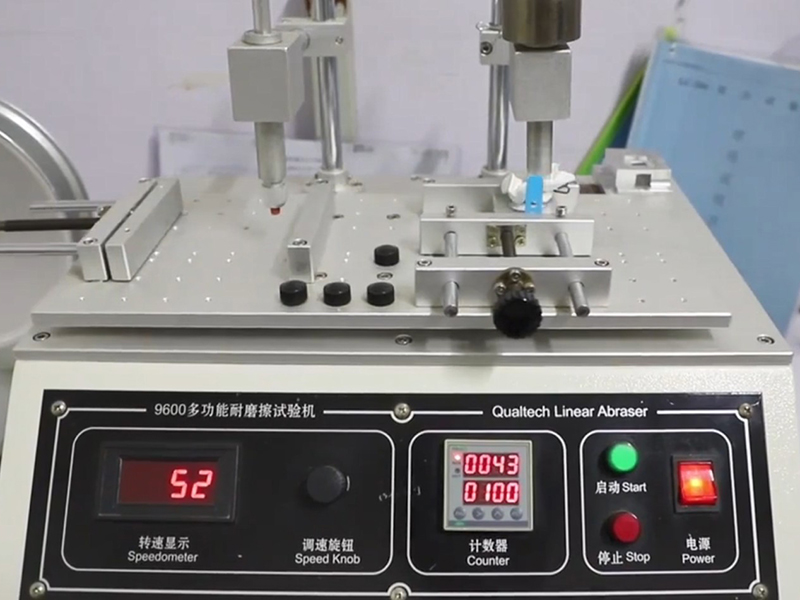

5. Strict Quality Inspection

Set up a special olfactory inspection link to ensure that every silicone water bottle undergoes a strict flavor assessment before leaving the factory, and substandard products are not allowed to enter the market.

In Summary

Consumers can effectively reduce the odor problem of silicone foldable water bottles through simple home treatment, while manufacturers need to start from the source material selection to every detail of the production process, the comprehensive use of a variety of strategies to fundamentally solve the odor problem, and work together to create a refreshing, healthy drinking water experience. In the future, with the advancement of material science and technology and the optimization of production technology, the odor problem of silicone water bottles is expected to be fundamentally improved, bringing consumers a more satisfactory experience.s