内容

健康的なライフスタイルを追求する今日のトレンドの中で、 シリコーン水筒 は、軽量で耐久性があり、落下しにくいという特徴から、多くの消費者に支持されている。しかし、筆者はアマゾンを含むいくつかの主要なeコマースプラットフォームを調査し、シリコン水筒の臭いが多くのユーザーのフィードバックの中で頻繁に言及される苦痛のポイントになっていることを発見した。本稿の目的は、消費者がどのようにしてシリコン水筒の臭いを効果的に除去できるかを論じるとともに、製造工程における臭いを除去する重要なプロセスを明らかにし、消費者により良い体験をもたらすことである。

シリコーン水筒の臭いを除去する消費者ガイド

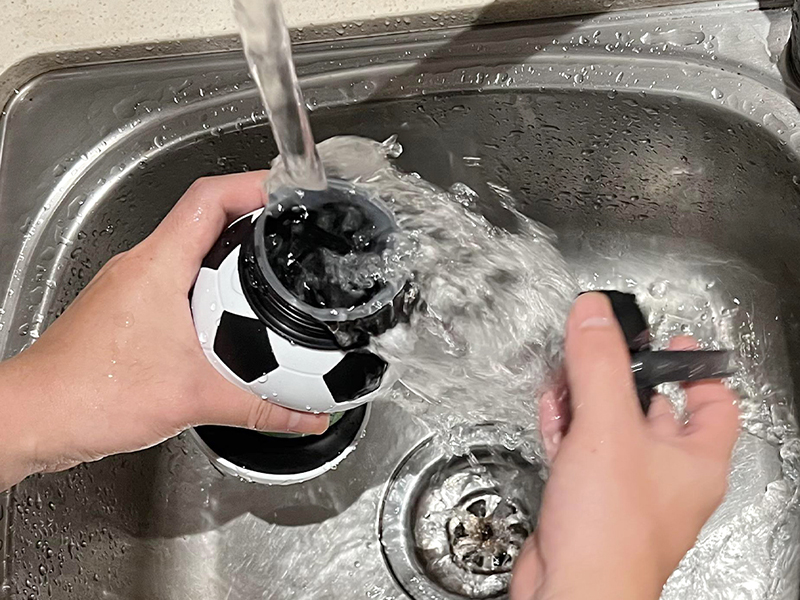

1. ぬるま湯で洗う

初めてお使いになる前に、ぬるま湯に少量の中性洗剤を入れて、シリコーン水筒の内側と外側をよく洗い、その後流水ですすいでください。

2. 沸騰水浸漬法

水筒に熱湯を注ぎ、しっかりと蓋をして数時間から一晩放置する。翌日、お湯を注ぎ、もう一度すすぎ、自然乾燥させる。

3. 自然療法:レモンジュース/酢

水にレモン汁かホワイトビネガーを数滴加え、ボトルをその溶液に数時間浸す。

4. 重曹の不思議な働き

重曹と水を混ぜてペースト状にし、水筒の内壁にまんべんなく塗りつけ、すすいだ後しばらく放置すれば、重曹の除染・消臭能力は侮れない。

生産工程における匂い管理

1. 原材料の選択

原料管理が鍵高品質で低VOC(揮発性有機化合物)の食品用シリコーン原料は、臭いの可能性を根本的に減らすことができる。

2. 放出剤の最適化

離型剤は臭気の主な発生源である。無臭で環境に優しい食品用離型剤を採用し、製造後の洗浄を徹底することで、離型剤の残留を最小限に抑えることができる。

3. シリコーン水ボトルの二次加硫

これは製品の物理的特性を高めるだけでなく、残留臭気分子を完全に蒸発させるのにも役立つ。

4. シリコーン水筒の効率的な換気と保管

製造後、製品は風通しの良い環境に置かれ、残留臭を自然に放出させる。また、臭いの蓄積を抑えるため、密閉された空間での長期間の積み重ねは避ける。

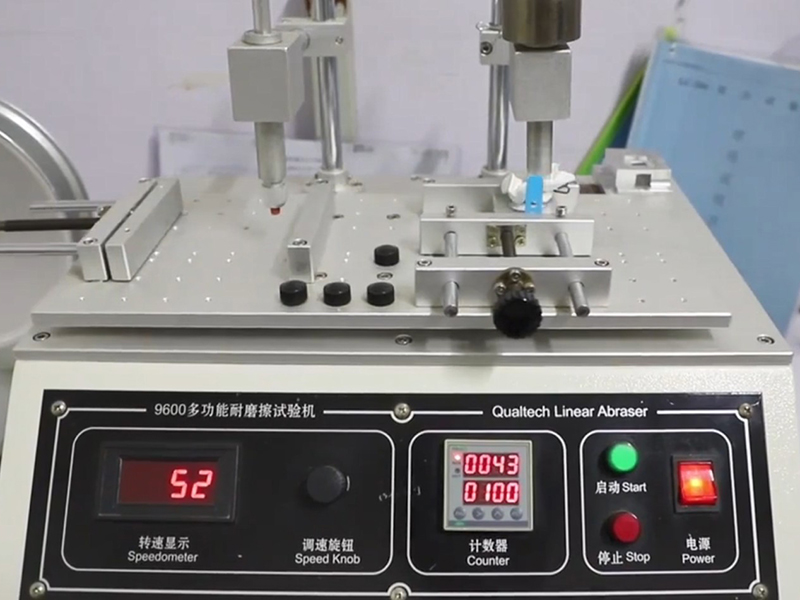

5. 厳しい品質検査

特別な嗅覚検査リンクを設置し、すべてのシリコーン水ボトルが工場を出荷する前に厳格な風味評価を受け、規格外製品が市場に出回ることがないようにする。

まとめ

消費者は簡単な家庭での処理でシリコーン製折りたたみ式水筒の臭気問題を効果的に減らすことができるが、メーカーは原料の選択から始まり、生産工程の細部に至るまで、様々な戦略を総合的に用いて臭気問題を根本的に解決し、爽やかで健康的な飲料水体験を創造するために協力する必要がある。今後、材料科学技術の進歩と生産技術の最適化により、シリコーン水ボトルの臭気問題は根本的に改善され、消費者により満足のいく体験をもたらすことが期待される。