콘텐츠

건강한 라이프스타일을 추구하는 오늘날의 트렌드에서, 실리콘 물병 는 가볍고 내구성이 뛰어나며 낙하 방지 기능이 있어 많은 소비자들이 선호합니다. 그러나 필자가 아마존을 포함한 여러 주요 이커머스 플랫폼을 조사한 결과, 실리콘 물병의 냄새가 많은 사용자 피드백에서 자주 언급되는 불만 사항이라는 사실을 발견했습니다. 이 글의 목적은 소비자가 실리콘 물병의 냄새를 효과적으로 제거할 수 있는 방법을 논의하고 생산 과정에서 냄새를 제거하는 핵심 프로세스를 공개하여 소비자에게 더 나은 경험을 제공하는 것입니다.

실리콘 물병의 냄새 제거를 위한 소비자 가이드

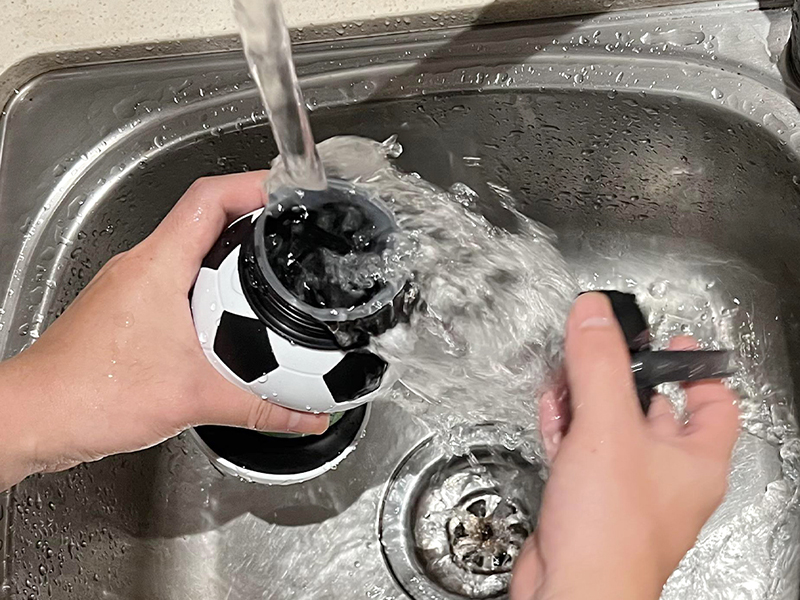

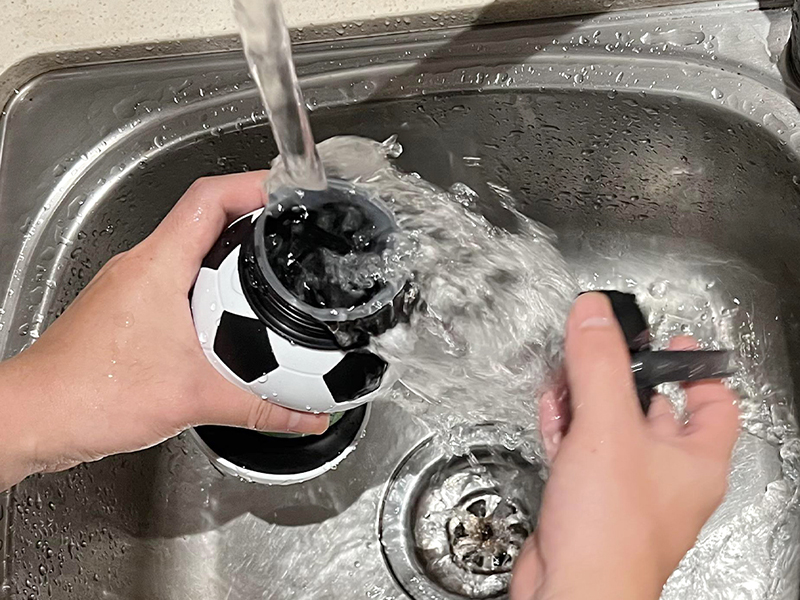

1. 따뜻한 물로 씻기

처음 사용하기 전에 따뜻한 물과 소량의 중성 세제를 사용하여 실리콘 물병의 내부와 외부를 철저히 씻은 다음 흐르는 물로 헹구면 표면에 부착 된 불순물과 초기 냄새를 제거하는 데 도움이됩니다.

2. 끓는 물에 담그는 방법

물병에 끓는 물을 붓고 뚜껑을 단단히 닫은 후 몇 시간 또는 밤새 두면 고온이 냄새 분자의 방출을 촉진하는 데 도움이 됩니다. 다음 날 물을 붓고 다시 헹구고 자연 건조하세요.

3. 자연 요법: 레몬 주스/식초

물에 레몬즙이나 백 식초 몇 방울을 떨어뜨린 후 병을 용액에 몇 시간 동안 담가두면 천연 산성 성분이 냄새를 중화시키고 그 후에 깨끗이 헹굽니다.

4. 베이킹 소다의 놀라운 효과

베이킹 소다와 물을 반죽으로 섞어 물병 내벽에 고르게 코팅하고 헹군 후 얼마 동안 방치하면 베이킹 소다의 오염 제거 및 탈취 능력을 과소 평가해서는 안됩니다.

생산 공정에서의 냄새 관리

1. 원자재 선택

소스 제어가 핵심입니다. 고품질의 저-VOC(휘발성 유기 화합물) 식품 등급 실리콘 원료를 사용하면 냄새 발생 가능성을 근본적으로 줄일 수 있습니다.

2. 릴리스 에이전트 최적화

이형제는 냄새의 주요 원인입니다. 무취의 친환경 식품 등급 이형제를 채택하고 생산 후 철저한 세척을 통해 이형제 잔류물을 최소한으로 줄입니다.

3. 실리콘 물병의 2차 가황 처리

실리콘 물병을 성형한 후에는 2차 가황 공정, 즉 고온에서 추가 경화 과정을 거쳐 제품의 물리적 특성을 향상시킬 뿐만 아니라 잔류 냄새 분자를 완전히 증발시키는 데 도움이 됩니다.

4. 실리콘 물병의 효율적인 환기 및 보관

생산 후 제품은 통풍이 잘되는 환경에 두어 잔류 냄새를 자연스럽게 배출하고 밀폐된 공간에 장시간 쌓아두지 않아 냄새가 쌓이는 것을 방지합니다.

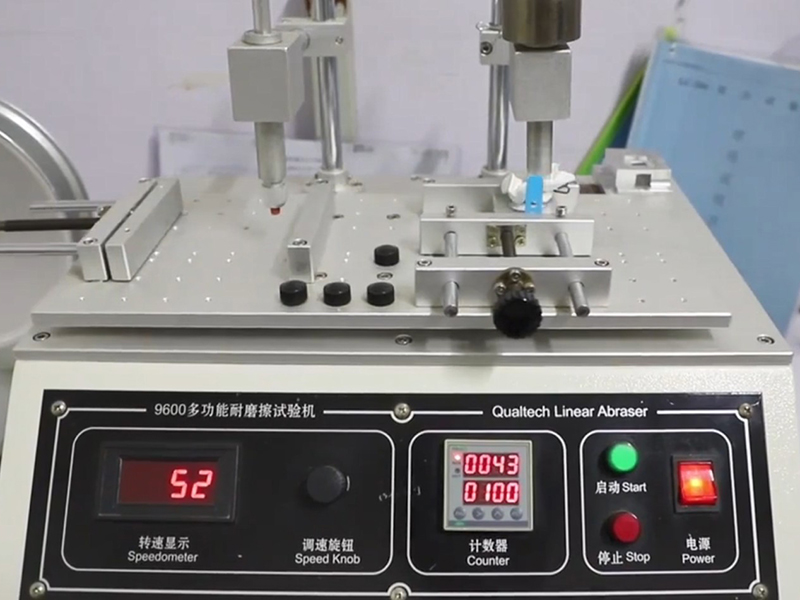

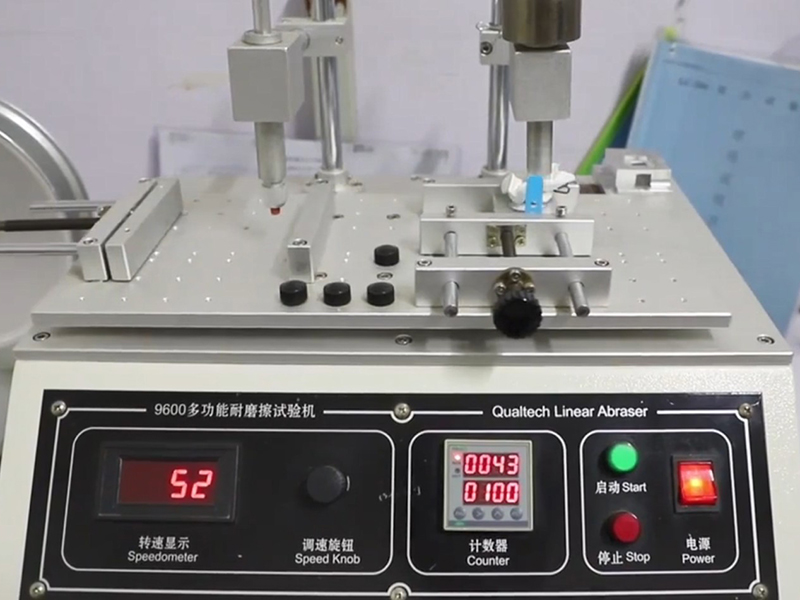

5. 엄격한 품질 검사

모든 실리콘 물병이 공장에서 출고되기 전에 엄격한 맛 평가를 거치도록 특별 후각 검사 링크를 설정하고, 기준 미달 제품은 시장에 출시되지 않도록 합니다.

요약

소비자는 간단한 가정 처리를 통해 실리콘 접이식 물병의 냄새 문제를 효과적으로 줄일 수 있으며 제조업체는 원료 선택부터 생산 공정의 모든 세부 사항, 다양한 전략을 포괄적으로 사용하여 냄새 문제를 근본적으로 해결하고 상쾌하고 건강한 식수 경험을 만들기 위해 함께 노력해야 합니다. 앞으로 재료 과학 기술의 발전과 생산 기술의 최적화로 실리콘 물병의 냄새 문제가 근본적으로 개선되어 소비자에게 더 만족스러운 경험을 제공 할 것으로 예상됩니다.