What is Silicone Over-Molding?

Introduction to Silicone Over-Molding

Silicone over-molding is a sophisticated manufacturing process where silicone is molded onto, around, or through a substrate material to create a finished product. Often referred to as Silicone Rubber Compression Over-molding or Liquid Silicone Rubber (LSR) Over-molding, this technique is used to combine the best features of different materials in one product. By over-molding silicone onto other substrates such as plastics, metals, or electronics, manufacturers can achieve products with enhanced properties, including better durability, flexibility, and usability. This process allows designers to take advantage of varying hardness and rigidity, offering a solution for complex designs.

Types of Silicone Over-Molding

Silicone over-molding can be used with a variety of substrates, including metals, plastics, and even silicone itself. Here are the different types of silicone over-molding:

Silicone Over Silicone

In this method, a silicone substrate is first molded, followed by molding another layer of silicone over or around it. The two layers of silicone may differ in hardness or color, allowing for customized properties in the final product. This process is commonly used for creating multi-layered parts with varying degrees of flexibility.Silicone Over Plastic

This is one of the most common silicone over-molding methods. First, a rigid plastic substrate is molded, and then a soft silicone layer is molded onto or around it. This technique is often used to provide a soft grip or cushioning to a rigid plastic part, improving ergonomics and comfort. Liquid Silicone Rubber (LSR) is often used in this process due to its versatility and ease of molding.Silicone Over Metal

In this method, a metal substrate, which may be machined, cast, or formed, is inserted into a silicone compression molding tool. Silicone is then molded over or around the metal. This process is frequently used in applications where metal components need to be encapsulated in silicone for enhanced durability, protection, or sealing purposes.

Benefits of Silicone Over-Molding

The silicone over-molding process offers several key benefits, making it an ideal choice for various industries:

Cost-Effectiveness & Time Savings

By molding silicone directly onto substrates like metal or plastic, manufacturers can significantly reduce the cost and time associated with assembling separate parts. This streamlines production, lowers labor costs, and accelerates time-to-market, making it a more economical solution for complex designs.Enhanced Design Flexibility

Silicone over-molding allows for intricate and complex designs that would otherwise be difficult to achieve with separate assembly steps. This includes the creation of parts with multiple colors, textures, or functional components in a single mold, reducing the need for additional processing.Superior Surface Finish & Bonding

The silicone over-molding process produces a high-quality surface finish and excellent bonding between the silicone and the substrate. This ensures consistency in part thickness, clean surfaces, and strong adhesion, making it ideal for creating long-lasting, durable products.Improved Durability & Functionality

Silicone over-molding enhances the overall durability of the final product by adding protective layers or soft touch points to rigid components. This makes the product more resistant to wear, impact, and environmental stress.Versatility in Applications

Silicone over-molding is versatile and can be applied in a wide range of industries, offering tailored solutions for various needs. The combination of materials provides enhanced mechanical and thermal properties, making silicone over-molded products suitable for challenging applications.

Common Applications of Silicone Over-Molding

Silicone over-molding is used in various industries to produce a wide range of functional and aesthetic products, including:

Wearable Devices

Silicone over-molding is widely used in the production of wearable tech products such as fitness trackers, smartwatches, and medical devices. The combination of silicone with other materials ensures flexibility, durability, and comfort.Mechanical Reinforcements

Silicone over-molding is often used in creating gaskets, seals, and fluidic components, offering enhanced protection, sealing, and durability.Medical Applications

Silicone over-molding is used for manufacturing medical catheters, implants, and other medical devices where biocompatibility, flexibility, and durability are essential.Consumer Products

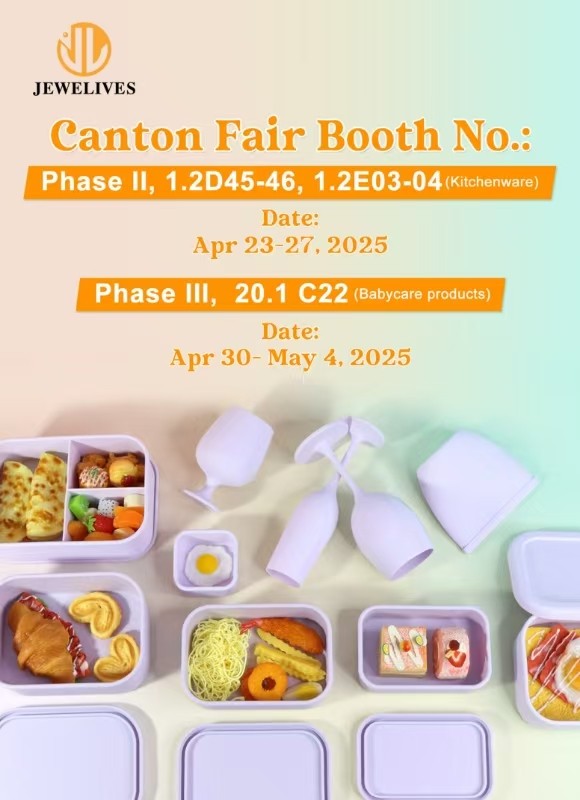

Silicone over-molding is ideal for creating baby products such as pacifiers, teethers, and bottles, as well as promotional items. The process allows for safe, non-toxic, and functional products that are highly customizable.Food Contact Products

Silicone over-molding is also used in products like bakeware, ice cube trays, chocolate molds, and other kitchen items. These silicone products are safe for use with food and can be easily molded to create intricate designs.

结论

Silicone over-molding is a versatile and cost-effective manufacturing process that combines the best of multiple materials. Its benefits, including time and cost savings, enhanced design flexibility, and improved durability, make it an ideal solution for industries ranging from consumer goods to medical applications. As the demand for customized, durable, and high-quality products continues to grow, silicone over-molding is expected to play a critical role in shaping the future of manufacturing.