Contenido

1.The Impact of Silicone Tolerance Control on Product Functionality

Silicone tolerance control is of utmost importance in the manufacturing of silicone products. Even a tiny deviation of 0.1mm can lead to significant issues. For example, in silicone baby bottles, an inaccurate nipple hole size may cause the milk to flow too quickly or too slowly, potentially choking the baby or making it difficult for them to feed. Similarly, a poorly fitting silicone phone case might result in unresponsive buttons and misalignment with the charging port, leading to a 30% increase in user abandonment rates.

![]()

Take silicone pet feeders as another example. If the tolerance of the sealing part is not well controlled, it may lead to leakage of pet food or water, which not only affects the user experience but also reduces the product’s reputation. For silicone lunch boxes, improper tolerance control can cause the lid to not seal properly, resulting in food spillage and odor leakage. These issues highlight how crucial silicone tolerance control is for the functionality of various products.

2. Common Misunderstandings About Silicone Tolerance Control

There are several common misconceptions regarding silicone tolerance control that manufacturers need to be aware of.

2.1 The misconception that a smaller tolerance is always better

While it may seem that tighter tolerances are better, pursuing extremely tight tolerances like ±0.05mm can double the cost without necessarily improving functionality. It is essential to differentiate between critical dimensions and non-critical ones. For instance, the sealing surface of a silicone water bottle requires strict tolerance control, while decorative patterns on a silicone phone case may not need the same level of precision.

2.2 The belief that all industry standards are the same

Different industries have varying tolerance requirements. Medical silicone products have a tolerance of ±0.05mm due to the critical nature of their application. Consumer electronics typically have a tolerance range of ±0.1 to ±0.3mm, balancing cost and user experience. Industrial sealing components may allow for a tolerance of ±0.5mm to accommodate dynamic working conditions. For silicone baby products, the tolerance needs to be strictly controlled to ensure the safety and comfort of infants.

2.3 The assumption that molds are the only determining factor

Although molds are important, other factors like material shrinkage and curing process fluctuations also play significant roles. Liquid silicone has a shrinkage rate of 0.8% to 1.2%. A temperature variation of ±5℃ during curing can result in a dimensional change of ±0.1mm. For example, when producing silicone pet toys, if the material shrinkage is not properly accounted for, the final product may not meet the expected size and shape, leading to customer dissatisfaction.

3. Practical Strategies for Silicone Tolerance Control

Implementing effective tolerance control strategies is crucial for manufacturers to ensure product quality and meet customer requirements.

3.1 Anticipating shrinkage during the design phase

When designing silicone products, it is necessary to account for material shrinkage. The formula for mold size is: Mold Size = Finished Product Size / (1 – Material Shrinkage Rate). For example, if a silicone lunch box has a designed inner dimension of 100mm and the liquid silicone shrinkage rate is 1%, the mold inner dimension should be designed as 101mm. This helps to ensure that the final product meets the desired specifications.

3.2 Adopting a dynamic tolerance mindset

When dealing with components like silicone buttons on a phone case that mate with plastic housings, it is important to consider the resilience of silicone. Typically, a compression space of 0.2 to 0.5mm should be reserved to accommodate the rebound of silicone. This ensures that the buttons function properly and provide a good user experience.

3.3 Implementing process chain coordination

Several key control points in the manufacturing process affect tolerance:

- Mixing Uniformity: Ensures consistent shrinkage and product quality.

- Curing Temperature Curve: Determines the final dimensional stability and physical properties of the silicone product.

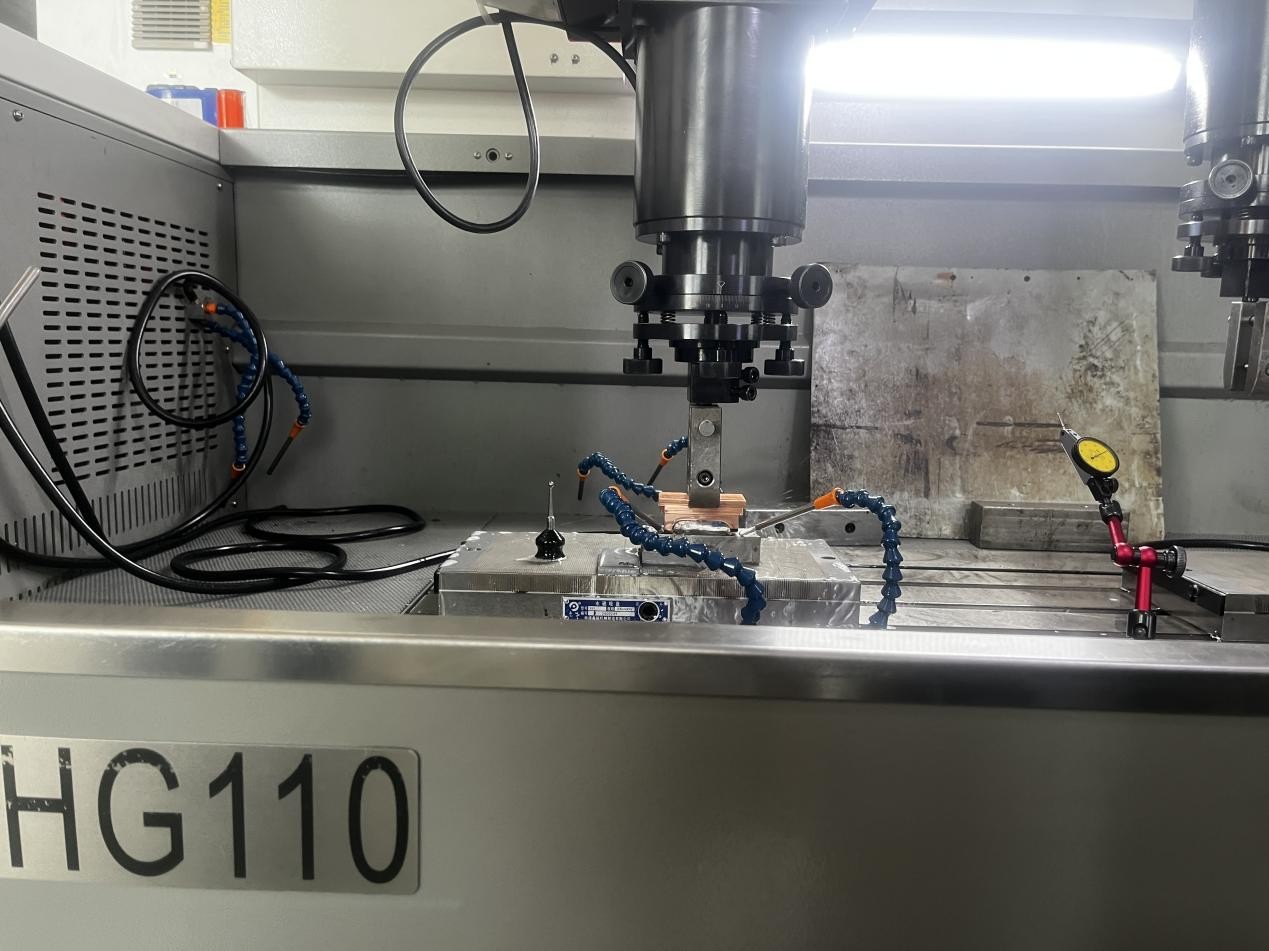

- Post – processing (such as CNC cutting): Can add precision of ±0.1mm, ensuring that products like silicone baby utensils have accurate shapes and smooth edges.

3.4 Reverse-engineering standards based on user scenarios

Extreme testing methods can help ensure product performance. For silicone water bottles used in outdoor activities, simulate temperature differences and physical impacts to check dimensional stability and durability. For baby silicone products, conduct extensive testing to verify whether deformation exceeds acceptable limits after prolonged use. For example, silicone baby bibs should be tested for flexibility and comfort after multiple washings and extended wear.

4. The Future of Silicone Tolerance Control

The industry is continuously evolving, and new technologies are emerging to enhance tolerance control in silicone product manufacturing.

AI prediction systems can analyze historical data to predict shrinkage rates with 40% higher accuracy. 3D scanning quality inspection can complete full-size scanning in 0.02 seconds, automatically sorting out defective products. Adaptive molds with temperature-control modules can dynamically adjust cavity dimensions to compensate for process fluctuations. These technological advancements help manufacturers improve tolerance control and produce high-quality silicone products more efficiently.

In today’s consumer-upgrade era, user expectations for silicone products go beyond mere functionality. They demand products that are both user-friendly and durable. Silicone tolerance control is a key factor that can differentiate brands in the market. By understanding and implementing effective tolerance control strategies, manufacturers can enhance product quality, meet customer expectations, and gain a competitive edge in the silicone product industry. Whether it’s silicone water bottles, lunch boxes, baby products, phone cases, or pet supplies, proper tolerance control ensures that each product meets the highest standards of quality and performance.