21세기 제조 분야에서 실리콘은 다기능 고성능 소재로서 정밀 전자 부품 패키징부터 일상 생활 주방용품 제품에 이르기까지 어디에나 존재하며, 그 인기는 다음과 같습니다. 실리콘 제품 재료 과학의 급속한 발전을 목격했습니다. 글로벌 산업 환경의 지속적인 발전과 함께 실리콘 산업은 기회와 도전으로 가득한 새로운 시대에 접어들었습니다. 실리콘 산업에 있어 평범해 보이는 2024년은 업계 기업들이 전례 없는 적응력과 혁신을 입증해야 하는 일련의 복잡하고 심오한 변화를 예고하고 있습니다.

![]()

- 실리콘 제품의 원자재 가격 변동

실리콘 생산은 실리콘 원재료에 의존하며, 글로벌 경제 변동성, 공급망 불안정 또는 원재료의 원산지 변경은 원재료 가격 변동으로 이어져 생산 원가를 상승시키고 수익 마진에 영향을 미칠 수 있습니다. - 국제 무역 환경의 불확실성

국내 생산 능력 향상으로 실리콘 금형 수입은 감소했지만, 글로벌 무역 환경의 불확실성(관세 정책, 무역 마찰 등)은 여전히 업계 수출에 영향을 미칠 수 있으며, 특히 해외 시장 의존도가 높은 업체들의 경우 수출에 어려움을 겪을 수 있습니다. - 환경 보호 및 지속 가능성 요구 사항

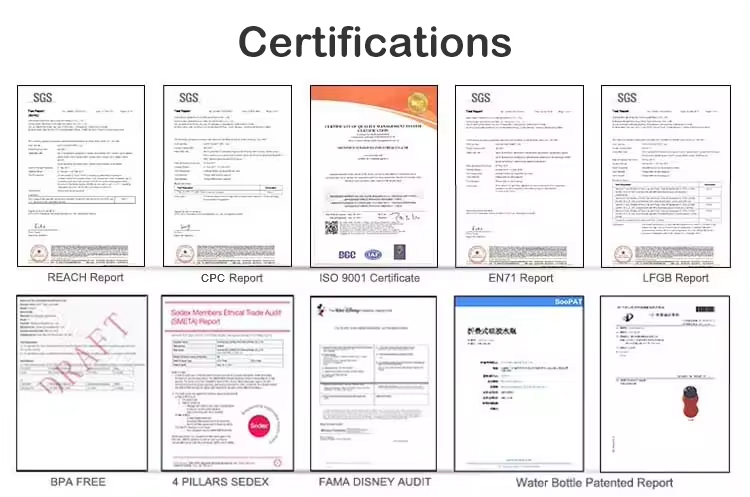

환경 보호에 대한 전 세계적인 인식이 높아지면서 실리콘 산업은 더욱 엄격한 환경 규제와 지속 가능한 제품에 대한 소비자 선호에 대응해야 합니다. 이에 따라 기업들은 생분해성 또는 친환경 실리콘 제품을 개발하는 동시에 환경 오염을 줄이기 위해 생산 공정을 개선해야 합니다. 쥬얼리브의 실리콘 제품은 RoHS, PAHs, REACH, FDA/LFGB 등 여러 국내외 환경 보호 인증을 획득하여 안심하고 구매할 수 있습니다.

- 실리콘 제품의 기술 혁신

다양한 산업 분야에서 고성능, 다기능 실리콘에 대한 수요를 충족하기 위해 기업은 기술 연구 개발과 혁신을 지속적으로 수행해야 합니다. 여기에는 제품 온도 저항, 기계적 특성, 투명성 등을 개선하는 것뿐만 아니라 생산 효율성 향상과 자동화 및 지능형 제조 기술 적용에도주의를 기울여야합니다. 환경 보호, 유행, 휴대용 기능, 고강도, 변형이 쉽지 않고 높은 투과율, 시장에서 널리 호평을받는이 실리콘 와인 잔의 최신 연구 및 개발. - 대체 소재의 위협

재료 과학의 발전으로 전통적인 실리콘 제품을 대체할 수 있는 새로운 소재가 등장할 수 있으며, 실리콘 업계는 제품의 고유한 가치와 대체 불가성을 지속적으로 입증해야 합니다. - 글로벌 경제 상황

세계 경제의 전반적인 건전성은 실리콘 제품에 대한 수요에 영향을 미칠 것이며, 특히 실리콘이 널리 사용되는 건설, 자동차, 전자 및 기타 산업에서 경기 침체로 인해 실리콘 수요가 감소할 수 있습니다.결론적으로에 따르면 실리콘 산업은 2024년에 기술 혁신, 시장 다각화, 비용 관리 및 규정 준수를 통해 해결해야 할 여러 가지 과제에 직면할 것으로 예상됩니다.