Zawartość

Teething is a challenging milestone for both babies and parents. Choosing a safe and effective teething solution is essential to soothe sore gums and support healthy oral development. Among the many options available—wood, plastic, rubber, gel—silicone baby teethers have become one of the most recommended choices for modern parents.

But how safe are silicone teethers, really?

In this article, we’ll explore the safety of silicone baby teethers, explain how to choose the right one, highlight common concerns, and share everything you need to know about certifications, cleaning methods, and material quality.

What Are Silicone Baby Teethers?

Silicone baby teethers are soft, chewable items designed to soothe a baby’s inflamed gums during the teething phase (typically starting between 4–7 months). They are made from food-grade silicone, a non-toxic and flexible material that can be easily sterilized and shaped into baby-safe designs.

Silicone is a synthetic polymer derived from silica (sand) that is heat-resistant, durable, and widely used in baby feeding products, kitchenware, and medical devices.

Are Silicone Baby Teethers Safe?

1. Non-Toxic and Free from Harmful Chemicals

High-quality silicone teethers are:

BPA-free

Phthalate-free

PVC-free

Lead-free

According to the U.S. Food & Drug Administration (FDA), food-grade silicone is safe for use in contact with food and drink, making it ideal for infant products (FDA Source).

2. Hypoallergenic and Gentle on Gums

Unlike hard plastic or wooden teethers, silicone offers gentle resistance, making it more comfortable for sore and sensitive gums. Its softness reduces the risk of gum injury, especially during the early eruption of baby teeth.

3. Heat-Resistant and Dishwasher-Safe

Silicone is resistant to both high and low temperatures. You can safely:

Boil it for sterilization

Use it in a dishwasher

Chill it in the refrigerator for extra relief

4. Durable and Long-Lasting

Premium silicone withstands wear and tear—even with heavy chewing—and does not break or splinter like plastic, which reduces choking risks and makes it a cost-effective choice for parents.

Common Concerns: What to Watch Out For

Despite its benefits, not all silicone teethers are created equal. Here are a few safety factors every parent and buyer should consider:

1. Choking Hazards

Avoid multi-piece teethers or those with small detachable beads, which may pose a choking risk if they break.

Teething necklaces and bracelets worn by adults can be hazardous if babies chew them unsupervised or if the string breaks.

Tip: Wybierz one-piece molded silicone designs with no cords, small parts, or glued joints.

2. Poor-Quality Silicone

Low-grade silicone may contain fillers, leaving it sticky, oily, or with a chemical smell. These materials are harder to clean and may degrade faster.

How to identify poor-quality silicone:

Has an unnatural odor

Feels sticky or greasy

Becomes cloudy or cracked over time

Choose only platinum-cured, medical-grade or food-grade silicone from reputable manufacturers.

3. Bacterial Contamination

Teething toys go directly in the mouth. Without regular cleaning, they can accumulate saliva, milk residue, or dirt—perfect conditions for bacteria to grow.

Cleaning recommendations:

Wash after each use with warm soapy water

Sterilize in boiling water for 5 minutes weekly

Store in a clean, dry container

How to Choose a Safe Silicone Baby Teether

When selecting a teething toy for your child—or for your retail store—consider these critical factors:

Safety Checklist:

| Requirement | Why It Matters |

|---|---|

| One-piece design | Reduces choking risk |

| Soft, flexible texture | Gentle on gums |

| No cords or strings | Prevents strangulation |

| FDA or LFGB approved material | Certified non-toxic |

| Withstands boiling/disinfection | Łatwy do czyszczenia |

| No added dyes or fragrances | Avoids chemical exposure |

Key Certifications to Look For

To ensure your silicone baby products meet international safety standards, look for the following certifications:

| Certyfikacja | Region | Meaning |

|---|---|---|

| FDA | USA | Complies with U.S. food-contact safety standards |

| LFGB | Germany/EU | Highest safety standard for food-grade silicone |

| EN71 | EU | European toy safety certification |

| CE Mark | EU | Declares conformity with European safety legislation |

| CPSIA | USA | Complies with U.S. Consumer Product Safety rules for children |

| BPA-Free Mark | Global | Confirms absence of Bisphenol A |

Bonus Tip: Ask your supplier for test reports from certified labs like SGS, TUV, or Intertek.

Silicone vs. Other Teething Materials

| Materiał | Pros | Cons |

|---|---|---|

| Silikon | Soft, safe, heat-resistant, durable | Must ensure quality (avoid fillers) |

| Wood | Natural, biodegradable | Can splinter, harder to clean |

| Tworzywo sztuczne | Cheap, lightweight | May contain BPA, breaks easily |

| Natural rubber | Soft and eco-friendly | Shorter lifespan, allergy potential |

| Gel-filled | Cooling relief | Risk of leakage or ingestion |

Environmentally Friendly Silicone Options

Although silicone is not biodegradable, it is highly durable and reusable, making it a more sustainable option than single-use plastics. Some brands now offer eco-conscious silicone products made from sustainable production methods.

Alternative: For fully biodegradable options, consider natural rubber teethers, though they may lack durability.

Final Thoughts: Are Silicone Teethers Worth It?

Yes—high-quality silicone baby teethers are safe, effective, and parent-approved.

They offer a balance of safety, comfort, and practicality that makes them a superior choice for modern families. Just make sure to:

Choose teethers from trusted brands or certified suppliers

Avoid decorative designs that include beads or strings

Clean and inspect the teether regularly

Look for relevant certifications like FDA, LFGB, CE, or CPSIA

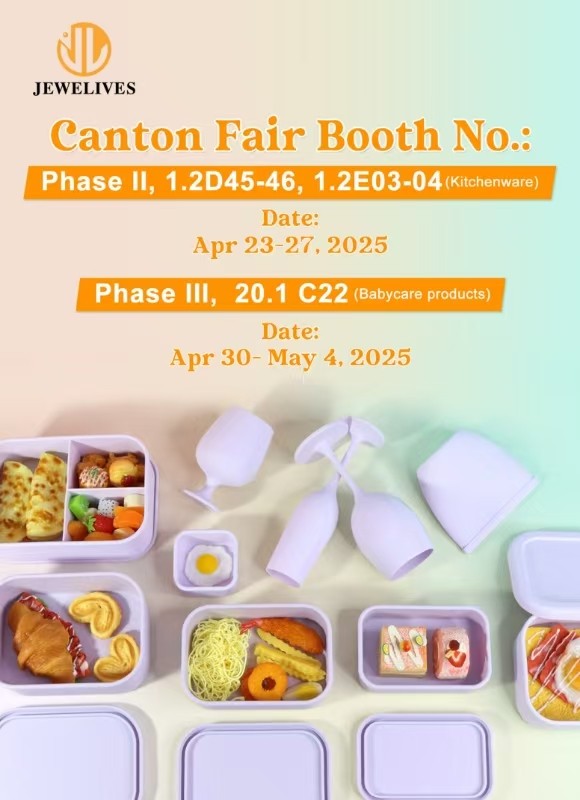

At Jewelives, we specialize in OEM & ODM production of silicone baby products for global brands. With over 21 years of manufacturing expertise and full certification (BSCI, Sedex, ISO9001, Disney FAMA, GMP), we ensure every product meets the highest safety and quality standards.